FS 515

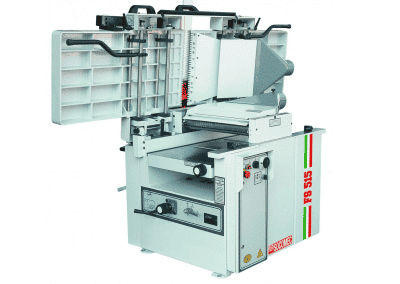

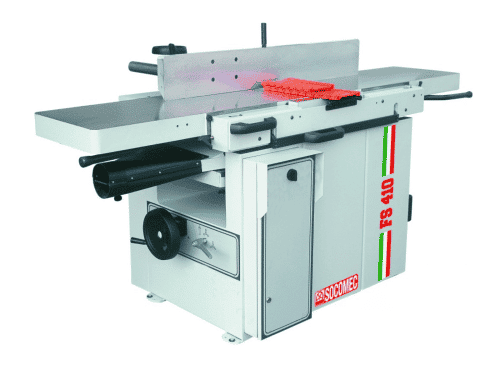

Socomec’s combined planer thicknesser is a woodworking machine used to make a rough surface flat and smooth or to reduce the thickness of a board to a set size as well as to bring to size a board with both surfaces perfectly straight and parallel to each other.

Technical Data

- Shaft motor power Kw (Hp) 4 (5,5)

- 4-knives shaft Ø Mm 110

- Rotation speed shaft r.p.m. 5000

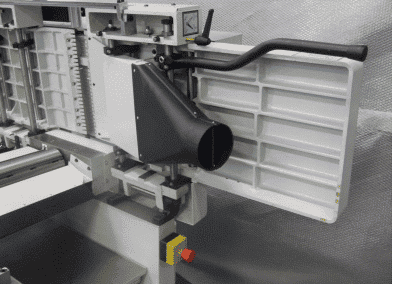

- Dust suction hood Ø mm 120

- Dimensions of surface working tables mm 2130×515

- Dimensions of thickness working tables mm 960×515

- Min / max working height mm 4/225

- In-feeding speed Mt/1’ 8 – 14

- Net weight kg 800

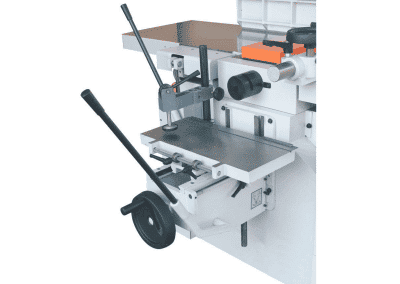

Mortising unit (on request)

- Cast iron table / dimensions mm 560×250

- Longitudinal/transversal/vertical stroke mm 250x160x200

- Wescott chuck Ø mm 0 – 16

Equipment

STANDARD EQUIPMENT

- Manual delta/star switch

- Cast iron – heat treated tables

- Simultaneous rise/fall of the surfacing tables

- Mechanical gauge for the height of thickness working

- Movement of the squaring fence on the surfacing table by means of an handle

- Knives-adjusting device

- Surfacing/thickness suction hood

- Maintenance manual and spanners

EQUIPMENT FOR “CE” NORMS

- Self-braking motor

- Low tension electric installation

- Surface safety guard mod. ‘TX’

Options on Demand

- Motor HP 7,5 KW 5,5

- Power rise-fall to thickness table

- 4-infeeding speeds gear

- 2 pieces of bed rolls

- MONOBLOC TERSA shaft

- 4 knives for TERSA shaft

- Rubber for out-feed top roller (

- Overload protection with emergency switch ( no CE version only )

- Self-braking motor with brake release, overload protection and emergency switch (no CE version only)

- Electronic read – out for rise/ fall of the thickness table

- Mortising unit with Wescott chuck and presser device

ASK FOR A QUOTE

Fill out the contact form to send us your request immediately.

We will reply via email or contact you within 48h to investigate your needs.