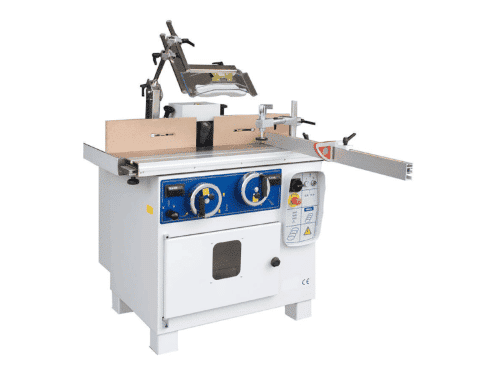

F 330

The spindle moulder for wood is a widely used type of cutter, it is used to make grooves, to profile the leafs of the panels and to carry out interlocking grooves. Our Toupie are particularly suitable for professional carpentry workshops, are entirely built in Italy and comply with EC regulations and the required parameters on the emission of noise and dust.

Technical Data

F 330

Overall dimensions of the carriage

- Motor power Kw (Hp) 5,5(7,5)

- Overall dimensions of the fixed cast iron table mm 1100 × 920

- Vertical stroke of the shaft mm (Ø 30-35=140) (Ø 40-50=180)

- 5-speeds of the shaftg/1’ 2500/4200/6000/8000/10000

- Net weight kg 560÷720

F 330 I

- Motor power Kw (Hp) 5,5(7,5)

- Overall dimensions of the fixed cast iron table mm 1100 × 920

- Vertical stroke of the shaft mm (Ø 30-35=140) (Ø 40-50=180)

- 5-speeds of the shaft g/1’ 2500/4200/6000/8000/10000

- Tilting shaft – 5° + 45°

- Net weight kg 560÷720

F 330 C

- Motor power Kw (Hp) 5,5(7,5)

- Overall dimensions of the fixed cast iron table mm 1100 × 640

- Vertical stroke of the shaft mm (Ø 30-35=140) (Ø 40-50=180)

- 5-speeds of the shaft g/1’ 2500/4200/6000/8000/10000

- Overall dimensions of the carriage mm 1100×320

- Net weight kg 560÷720

F 330 IC

- Motor power Kw (Hp) 5,5(7,5)

- Overall dimensions of the fixed cast iron table mm 1100 × 640

- Vertical stroke of the shaft mm (Ø 30-35=140) (Ø 40-50=180)

- 5-speeds of the shaft g/1’ 2500/4200/6000/8000/10000

- Tilting shaft – 5° + 45°

- Overall dimensions of the carriage mm 1100×320

- Net weight kg 560÷720

Equipment

STANDARD EQUIPMENT

- Manual delta/star switch

- Spindle Ø 30 mm

- Fine adjusting spindle moulder with mechanical reader and displacing piece in the middle

- Ø max hole in the table 330 mm

- Locking system for spindle

- Maintenance manual and spanners

EQUIP. – “CE” SAFETY REGULATIONS

- Self-braking motor

- Automatic delta/star starter

- Low tension electric installation

- Ø max tool 220 mm

- Mechanical gauge for rise/fall of the spindle

- Main safety protection for spindle shaft

- Guide for shaping hood

- Electric system for feeding device

- Speed’s indicator

Options on Demand

- Tilting spindle unit -5° ÷ + 45°

- In-feeding and out-feeding long cast iron table extensions with an extensible bar toward the operator: mod.F 330 L

- Heavy lateral tenoning carriage + fence, excentric presser and tenoning hood: mod. F330 T

- Heavy lateral tenoning carriage complete with fence, excentric presser and tenoning hood, in-feeding table extension in cast iron and extensible bar toward the operator: mod. F 330 TL

- Electric system with overload protection+emergency switch (suitable or no CE machine only)

- Right/left rotation for spindle shaft

- Electronic reader of shaft’s height

- Spindle Ø 1” ¼

- Spindle Ø 35 mm

- Spindle Ø 40 mm

- Spindle Ø 50 mm

- Control board on consolle

- Motorised rise/fall of the shaft with adjustable axe with ‘console’ control board

- 2 pcs fences for the hood

- Laminated alu fences for spindle

- Interchangeable spindle MK4

- Extra top spindle for MK4

- Alu tenoning fence device

- Tenoning safety hood (compulsory for tenoning mod. F 230C and F 230iC in CE version)

- Tilting support for feeding device

- Tilting support for feeding device (already mounted on the machine to be shipped)

- Sliding table with counter-frame

- Speed reader (suitable for no CE version)

- Inverter

- Motorised tilting spindle shaft

ASK FOR A QUOTE

Fill out the contact form to send us your request immediately.

We will reply via email or contact you within 48h to investigate your needs.